The die – Everything you need for cutting external threads

In this blog post you will learn all about the most important features of the cutting tool. The following questions are answered: How is a die made? Where are the holes for retaining screws, the through holes or chip holes, the thread teeth and the gate? What is the purpose of the peel cut in a die? Which tools do you need for the die?

Description of the die

When it comes to dies, the name says it all: it is in fact a shaped piece of iron that can be used to cut threads into metal.

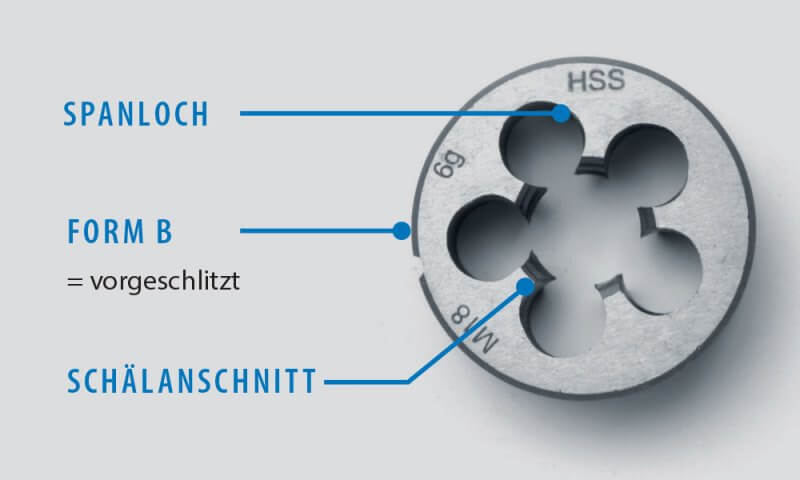

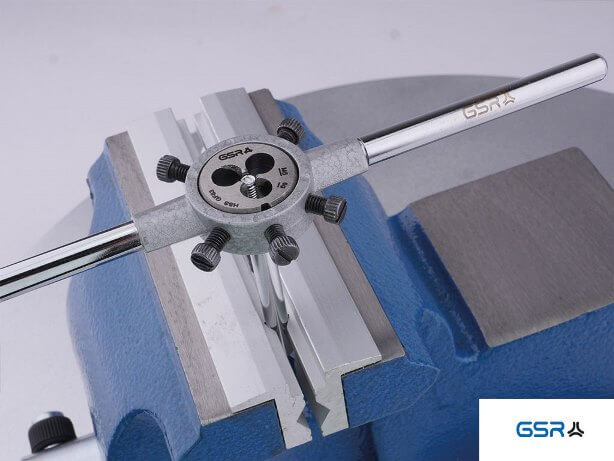

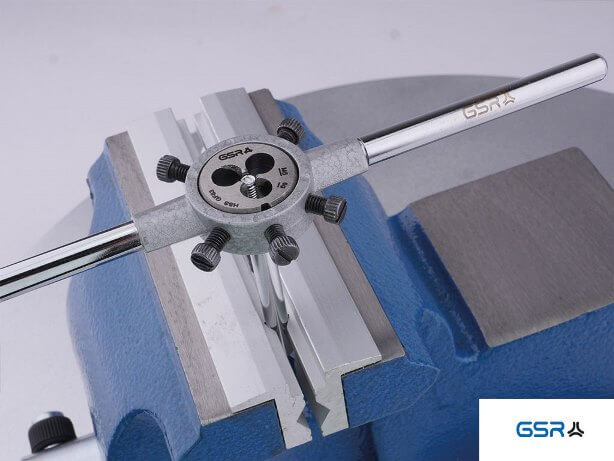

The cylinder of the die has four holes for holding screws and a slot (V-groove) on its shell side. Inside it there are three or more through holes that serve as chip holes. In the centre there is the threaded part with the corresponding thread ridges in the profile of the desired thread size. At the end of the webs there is a flattening on both sides. This is the so-called lead-in of the die.

Most important features of the die

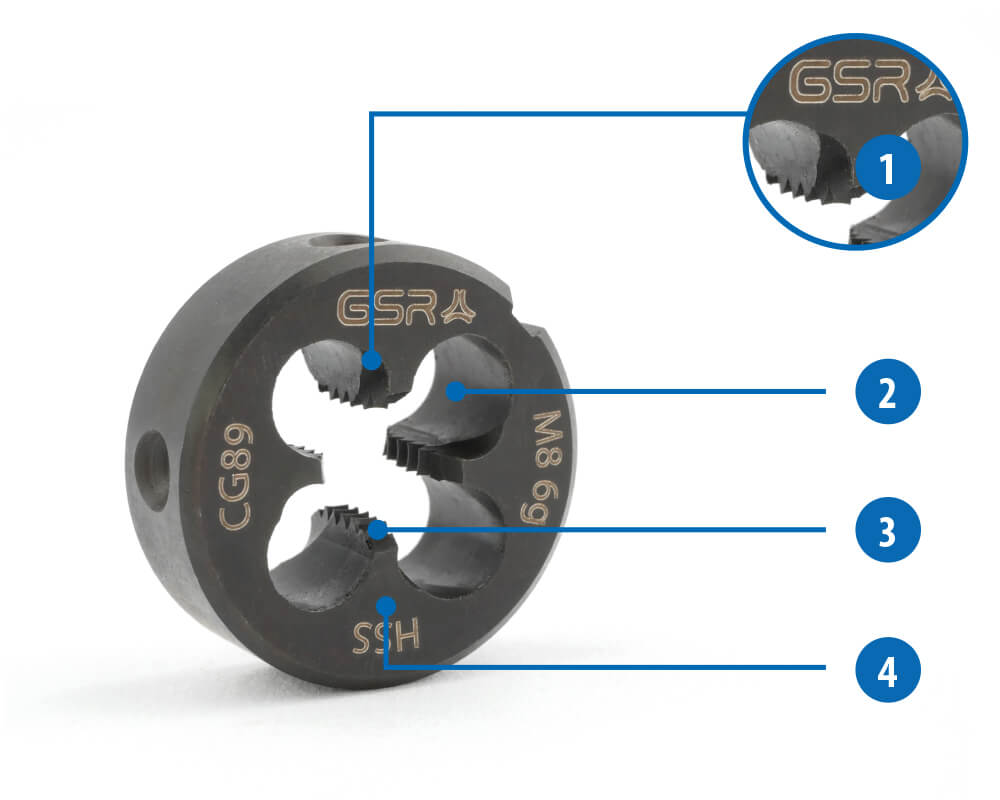

In the following overview screen you can see all the important characteristics of a die:

- Peel cut ensures a simplified first cut and good chip removal

- Tail hole

- thread part with studs

- Hole for retaining screws

- Form B = pre-slit with V-groove

Production type of the cutting die

A round bar with a corresponding outer diameter of steel is the starting material. With a hacksaw, corresponding cylinders are sawn off at the desired height. In the soft state, the outer holes, the inner holes and the V-groove are made and the contour of the cutting tool is chamfered. First, however, the core hole is drilled and the internal thread cut, then the chip holes are made. The product is then hardened. In the hard state, the first cut is ground, the surfaces are flattened and the insides of the chip holes are lapped. The inscriptions are then “lasered on”.

Dies – Types

There are different types of dies that are used in

DIN/EN 25968 are named. Usually the die is round and

pre-slit (form B). There are also slotted dies with and without

horizontal or vertical adjustment screw. However, these versions are available in

German market is hardly significant.

Dies are made of different materials: HSS dies for cutting steel up to 800 N/mm2 or HSSE dies for cutting stainless and acid-resistant steels. Their performance can be optimized by nitriding and vaporizing. However, there can also be square dies or hexagonal dies (so-called hexagonal die nuts for recutting threads or for cutting threads in hard-to-reach places).

Another distinguishing feature is the lead-in: dies can have a straight lead-in on both sides or a peeling lead, which improves chip removal.

Tools for die cutting

To insert a die, you need a die holder. There are die holders for manual operation or holders for dies that are clamped on a lathe in the tailstock or in the chuck of a drill / cordless screwdriver. In order to guarantee a straight cut, guides are used in the dimension of the pre-machining diameter. More information about the

bolt diameter can be found here!

By the way you will find die holders in our shop:

- Die holder in all sizes

Dies in all sizes and shapes are available here:

- Round die M Metric ISO thread

- Premium die vaporizes HSSE-Vap for stainless steels

- Round die MF Metric ISO fine thread

- Die BSF (British Standard Fine)

- Die BSP (British Standard Pipe)

- Dies BSW (British Standard Whitworth Coarse)

- Dies UNC (Unified Coarse Thread Series)

- Round die UNF (Unified National Fine Thread)

- Hexagon cutting nut M Metrisch

- Hexagon cutting nut BSP (British Standard Pipe )