in

The Ultimate Introduction To Hydraulic Torque Wrenches

What Is Hydraulic Torque Wrench?

Hydraulic torque wrenches are specially designed bolting tools for applications that have space limitations or require high output torque, and are mainly used to tighten or remove large bolts. Mainly used in shipbuilding, petrochemical, construction, electric power, mining, metallurgy and other industries, hydraulic wrench is a very important torque machine for installing and removing large bolts. It is easy to use and light in weight, and the torque provided is huge and precise. The maximum torque repeatability is approximately 3%.

Who Invented The Torqueing Tools?

The hydraulic spanner wrench was first conceptualized in 1960 and was later invented by George Sturdevant in 1968. Later, engineers carefully studied the physical principles of tools for tightening bolts, thereby improving the consistent and correct method of measuring and applying force. Together with the advancements in technology and usability made by bolting tools manufacturers, the current hyd torque wrench was created.

How Does A Bolting Tools Work?

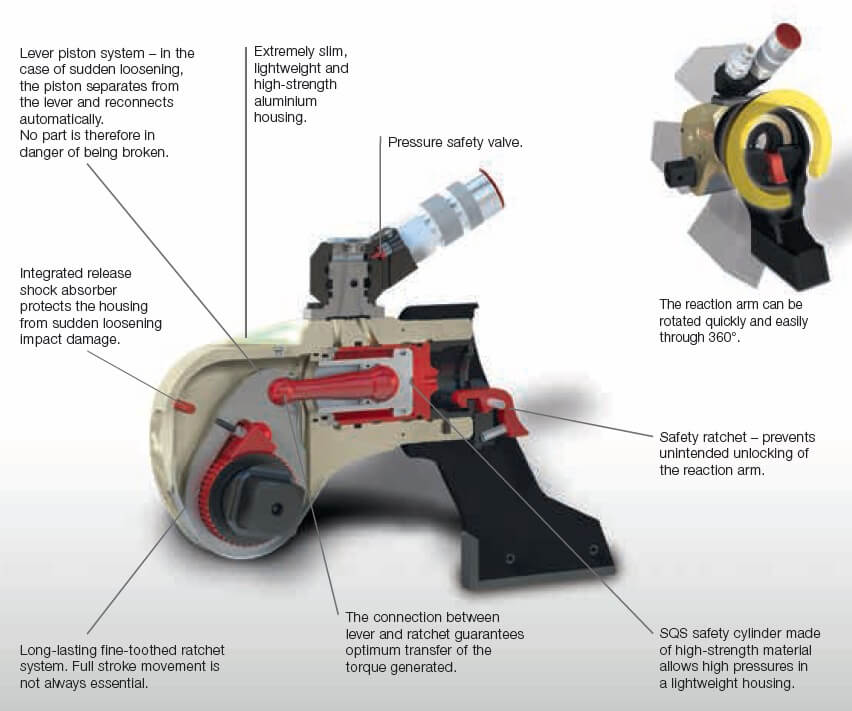

The design of the torque machine utilizes the huge leverage force generated by the hydraulic piston, and high-pressure hydraulic power is provided by a pneumatic or electric hydraulic pump.

The hydraulic piston is connected to the ratchet by a reaction pawl assembly that allows it to engage with the ratchet teeth in advance mode to rotate the nut or bolt head, and then release during the retraction of the piston to re-engage to the next forward push position.

All hydraulic power wrench work under a maximum hydraulic pressure of 700 bar, with double-acting heavy-duty hydraulic pistons, quick and easy to operate, and can be used to tightening or loosening nuts/bolts accurately.

Generally speaking, hydraulic torque tools are mainly used for the installation and removal of bolts with a diameter greater than one inch. It is powered by hydraulic pressure and provides high torque. The maximum output torque of the bolting equipment can reach 140,000Nm.

The tool for tightening nuts is composed of a working head, a hydraulic torquing machine and a high-pressure oil pipe. The hydraulic pump transmits power to the working head through the high-pressure oil pipe, and drives the working head to rotate to complete the tightening or loosening of the nut. The hydraulic torque pump can be driven by electricity or compressed air.

The working head of the hydraulic high torque wrench is mainly composed of three parts, the frame (also called the shell), the oil cylinder and the transmission parts.

The oil cylinder outputs force, and the piston rod of the oil cylinder and the transmission part form a movement pair. The distance from the center of the cylinder to the center of the transmission component is the arm of the hydraulic spanner wrench. The output of the cylinder multiplied by the arm is the theoretical output torque of the hydraulic torquing tools. Due to the friction resistance, the actual output torque of the big torque wrench is smaller than the theoretical output torque.

The Characteristics And Differences Of Square Torque Wrenches And Low Profile Hydraulic Wrenches:

Bolt tighting machine are generally divided into square drive hydraulic torque wrenches and low profile hydraulic torque wrenches.

The hydraulic square drive torque wrench has a protruding drive shaft and needs to be used with a standard socket. It is a general-purpose hydraulic bolt torque wrench with light weight, high strength, super torsion strength, fast operation cycle, fine tooth pawl and floating piston design. Suitable for all applications, it has high reliability, good operation safety and long service life.

TorcStark has a variety of square drive hydraulic wrenches, such as coaxial drive hydraulic torque wrench series, universal drive hydraulic torque wrench series, drive hydraulic wrench sockets, 1 2 square drive torque wrench, 3 4 square drive torque wrench, 3 8 square drive torque wrench…

The hollow hydraulic torque wrench is directly sleeved on the bolt for tightening or disassembly. It is small in thickness, light in weight, and high in strength, and is especially suitable for working in places with relatively small space. The low clearance wrench is very good in reliability and safety. It is made of aviation aluminum-titanium alloy material, and the quality is beyond doubt.

TorcStark produces various types of low profile torque wrenches, such as cassette type hydraulic wrench series, wheel type cassette drive type torque wrench series, split type drive type hydraulic torque wrench series, and special reducing sockets.

How To Correctly Use Hy Torque Wrench For Beginners?

The correct use of nut bolt tightening tools is divided into the following steps:

Assemble And Connect Hydraulic Spanner Components

The torque wrench machine will be disassembled for transportation and must be assembled before it can be used. Connect the hose to the hydraulic power pack and connect the other end to the high torque wrench. Then install a mobile handle on the side of the hydraulic wrench, and sometimes a reaction arm should also be installed. Tighten all fittings and make sure that all fittings are firmly connected.

Setting Adjustment

All best hydraulic torque wrenches have adjustable settings, and you can set specific torque values for specific items. If your project has a predetermined torque value, you should follow the steps below to set the torque.

After determining the required torque, use the torque conversion table to determine the pressure required to achieve the torque.

1. Connect the bolting tools to the power source and turn on the hydraulic torque wrench pump.

2. Press the advanced remote control button to display the pressure on the pressure gauge.

3. To adjust the pressure, first loosen the nut that locks the pressure adjustment handle, then turn the handle clockwise to increase the pressure, and turn the handle counterclockwise to decrease the pressure. When reducing the pressure, always reduce the pressure below the required point, and then restore the pressure gauge to the required pressure.

4. After reaching the required pressure, re-tighten the lock nut and turn the tool again to confirm that the required pressure setting has been obtained.

If there is no recommended specific torque setting, start with the lowest setting and work on it, then gradually increase it, taking care not to overtighten any fasteners.

When you need a reaction arm, follow the steps below.

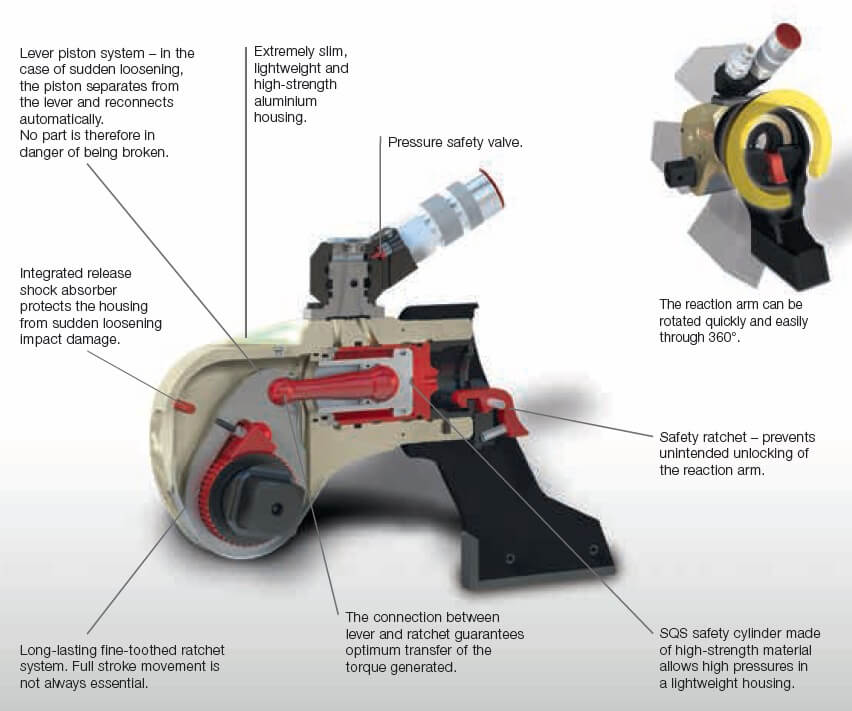

All TorcStark hydraulic torque wrenches are equipped with reaction arms. These reaction arms are used to absorb and counteract the forces generated during the operation of the device. The reaction arm should rotate in the same direction as the drive; however, it may be slightly adjusted to suit your specific application.

The reaction arm can be placed in multiple positions within a 360° circle. However, to position the arm correctly, it must be placed in the 90° quadrant of the circle. This quadrant is the area between the protruding drive and the bottom of the housing away from the rotation inlet. Always face the lower half of the housing and one side of the housing when tightening, and on the other side of the housing when loosening.

You Can Follow The Steps Below To Use A Nut Tightening Machine(Bolting Tools)

After connecting the hydro wrench to the hose, make sure the washers are properly aligned. A gasket is not always needed, but for some projects, it is essential. Press the two pipes together as much as possible (unless this is done mechanically), and then activate the hyd torque wrench. The pressure regulator should be loosened to make any final adjustments to the hydraulic torque wrench.

At the same time, you need to be familiar with your own bolt torquing machine model to properly perform this adjustment. Activate the hydraulic torque wrench to reach the correct torque. After this operation is completed, it will stop automatically, and you can loosen the hydraulic bolt tightening machine mechanism and remove it.

The following are the specific steps for the general hydraulic torque wrench square drive, the operation of the low profile torque wrench is the same.

1. Place the socket on the square drive, insert the socket fixing ring and pin, then place the socket on the nut, and make sure that the socket and the nut are fully engaged.

2. Place the reaction arm against an adjacent nut or other solid system component. Make sure there is a gap between the hose and the rotary joint. Do not allow the tool to react to the hose or rotary joint.

3. After starting the torque hydraulic pump and preset the pressure to the correct torque, press the remote push button to advance the piston assembly.

4. When the wrench is started, the reaction surface of the wrench or reaction arm will move against the contact point and the nut will start to rotate. Once the piston reaches the end of its stroke, press the remote return button to retract the piston.

5. Continue this forward and backward cycle operation until the nut no longer rotates and the pressure of the pump reaches the preset pressure. When the retract button is pressed, the piston rod will retract.

6. Continue to cycle the tool until it “stops” and reaches the preset torque. Wait until the nut stops rotating to reach the total torque.

Precautions For Torque Wrench Machine

1 Pay attention to the following matters when using hydraulic torquing tools to prevent safety problems.

2 Please be sure to carefully read all technical documents. This can help you solve a lot of problems.

3 Before use, please familiarize yourself with the wrench at least 3 times in the full size range. This will help you identify whether the moving parts are suitable.

4 Firmly hold the handle of the wrench, not the hose or other connections. When you apply the final torque, do not pull or push.

5 Do not use cracked or worn sockets. Keep a good distance from the socket when in use to protect yourself in case they break. When using an electric pump, ensure a good grounding and a suitable power supply voltage.

6 Exceeding the specified calibration range may damage your bolt tightening torque machine and put you in danger. At least every year, your wrench should be calibrated and checked by a professional calibration laboratory. If the wrench is dropped, re-calibrate and check.

7 If there is a possibility of air explosion in the environment of the workplace, electric hydraulic pumps should not be used, but pneumatic pumps should be used. If metal collisions produce sparks, precautions should be taken.

8 When using a hydraulic spanner, a suitable reaction fulcrum is required. Rotate the drive shaft of the torque wrench to observe, look for the fixed surface, and select the fulcrum to ensure reliable support of the reaction arm and ensure that the hydraulic tubing is not affected. Increase the system pressure, if the high torque machine jumps or shakes, stop and then readjust the reaction arm and fulcrum to make it stronger and safer.

9 The remote control for pump operation is only for bolt torquing tools. The operator should not be too far away from the pump.

10 The hydraulic torque spanner and wrench accessories that are not in use should be properly stored to avoid damage.

11 Do not use small hydraulic torquing equipment or hydraulic accessories to replace the work of hydraulic bolt torquing machine.

12 When using manual/electric hydraulic equipment, you should wear protective clothing such as gloves, helmets, safety shoes, ear protection, and labor insurance. Jewelry should not be worn.

13 Do not use hydraulic oil pipes, rotary joints, hydraulic power cords or external cables to drag the equipment. Do not bend or fold the oil pipe. Check the oil pipe frequently. If it is damaged, replace it.

14 All tools have dust cover and side cover to isolate the internal moving parts from the external environment. The user should not disassemble the tool without a protective device.

15 Make sure that all couplers are properly connected. Check the hydraulic tubing for tangles, make sure the drive shaft and cap are firm, and the joints are reliable. Ensure that all connectors, elbows, and rotary joints are not deformed or damaged.

Why Use A Hydraulic Torque Spanner?

1. According to relevant statistics, about 50% of equipment operation failures are caused by bolt problems, and the number of major equipment accidents caused by bolt problems is also very alarming. The high torque hydraulic wrench is a calibrated device that can accurately measure the torque required to tighten and achieve the required tightness, as well as the torque used to loosen, so that bolts can be loaded and unloaded perfectly.

2. It is not easy to tighten or loosen the bolts with a manual torque wrench according to the application. It may take several hours to tighten the bolts manually. This makes bolt torquing tools or hydraulic wrenches an indispensable tool in many industries that require efficient tightening of bolts.

3. The narrow space and inconvenient location during the operation make the size and weight of the hydraulic bolting tools become the most important indicator.

4. Hydrolic torque wrenches are ideal for heavy-duty bolt connections. Because torque tightening tools only generate torque hydraulically, this means that the user can tighten the bolts with very little effort.

5. The hydraulic tightening tools has an automatic ratchet and precise torque output. Compared with the traditional impact wrench or manual torque wrench, its design is easier to use and has many additional benefits, such as quieter, lighter and more accurate. Importantly, industrial bolting tools are designed to prevent insufficient torque and excessive torque. We all know that insufficient torque and excessive torque can bring huge losses, and hydraulic nut wrench can safely tighten large bolts and prevent disasters due to bolt problems.

Therefore, the use of bolt torquing equipment will bring faster progress and safer operations to your business.

Application Of Bolt Tightening Torque Wrench

Hydraulic wrenches tools have a wide range of applications and are suitable for electric power (nuclear power, wind power, hydropower, thermal power), ships, metallurgy, transportation, cement, construction, aviation, petrochemical, construction, mining and other industries. Hydraulic torque wrench tools are very important torsion tools for installing and dismantling large bolts, such as the installation and bolt fastening of wind power towers and blades, the bolt fastening of subway rails, and the bolt fastening of large mining carts in mines.

Because of the very strict requirements on the torque of bolt fixing and disassembly in the process of equipment installation, maintenance and repair, and manual operation is difficult to meet the requirements. Therefore, in most cases, hydraulic torque wrench machine are the most ideal choice for fixing and disassembling bolts that require large torque.

Where To Buy Hydraulic Torque Wrenches?

Before buying a best hydraulic torque wrench, you need to pay attention to some issues.

Know the type of hydraulic torque wrench that your project requires. If the working space of the wrench is narrow, it is necessary to choose a hollow hydraulic torque wrench, and a set of special reducing sleeves for love clearance hydraulic torque wrenches are required to adapt to bolts of different diameters.

Understand whether you are a heavy user or a temporary user of hydraulic power wrench, whether you need multi-function or general versatility, what size and maximum torque output, whether the material is steel or aluminum titanium alloy, which hydraulic nut tightening tool accessories you need, such as sockets, spare wrenches, Different sizes of reaction arms, safety handles, reducers, etc.

Buying a hydraulic torque wrench from TorcStark is a very good choice. You can tell our product experts about your needs or your business by email, and then we will provide you with the best product portfolio or customize it for you.

TorcStark is top hydraulic torque wrench manufacturer and supplier. Our hydraulic bolting equipment is made of aluminum-titanium alloy, which is light in weight and high in strength. Torcstark bolt tightening equipment have a complete range of categories and specifications, and the maximum torque can reach 150,000Nm. We have a complete supporting system supply capacity, and have passed CE, ISO9001 and other certifications.

Therefore, buying a hydraulic torque wrench from TorcStark is a very good choice. If you are looking for a hydraulic torque wrench with good quality and good price, please contact us via email(torcstark@gmail.com) get hydraulic torque wrench price list.