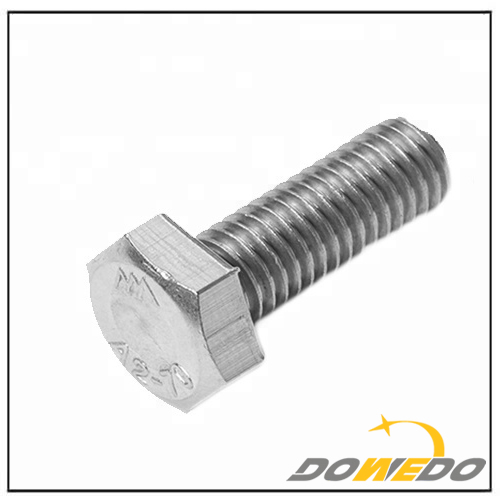

High Strength Hex Bolts

High strength hex bolts refer to performance grades above 8.8. They are usually more common in 8.8 and 10.9 and have greater tensile strength. Therefore, they are mainly used in outdoor projects such as wind power and dynamic machinery. When selecting high-strength hex bolts, it is generally considered from the perspectives of raw materials, strength grades and stress characteristics.

1 The raw materials

High-strength hex bolt is made of high-strength materials. The screws, nuts and washers of high-strength hex bolt are made of high-strength steel, usually 45 steel, 40 boron steel, 20 manganese titanium boron steel. Ordinary bolts are usually made of Q235 steel.

2 The strength level

High strength bolts are used more and more widely. Commonly used 8.8s and 10.9s two intensity levels, of which 10.9 level is mostly. Ordinary bolt strength grades are low, generally 4.4, 4.8, 5.6 and 8.8.

3 The perspective of stress characteristics

High strength hex bolts apply pre-tension and transmit external forces by friction. Ordinary bolt connection relies on the shearing of the bolt and the pressure of the hole wall to transmit the shear force. When the nut is tightened, the pre-tension is small, and the influence is negligible. However, the high-strength bolt not only has a high material strength, but also exerts a large bolt. The pre-tensioning force causes a pressing force between the connecting members, so that a large frictional force is perpendicular to the screw direction, and the pre-tensioning force, the anti-slip coefficient and the type of the steel directly affect the bearing capacity of the high-strength bolt.