During the bolt tightening process, only 10% of the torque is converted into clamping force. Do you believe it?

Have you heard that only 10% of the torque in the bolt tightening process is converted into clamping force? There is also a popular saying called the ‘541’ rule, that is, 50% of the torque in the bolt tightening process is to overcome the friction under the bolt head or nut, and 40% of the torque needs to overcome the friction in the thread pair. The torque actually converted into clamping force only accounts for 10%. Is this true?

Today we will use formula calculations to prove whether the above statement is correct!

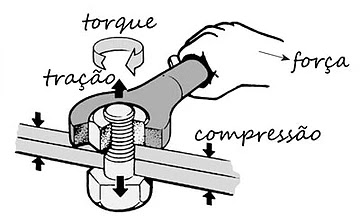

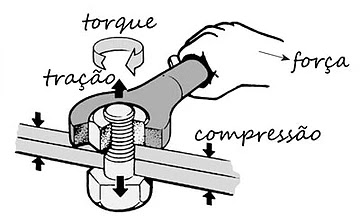

During the tightening process, part of the torque must overcome the friction between the nut and the connected part, part of the torque must overcome the friction between the threads, and part of the torque is to convert into the pre-tightening force of the bolt.

F0=bolt pre-tightening force

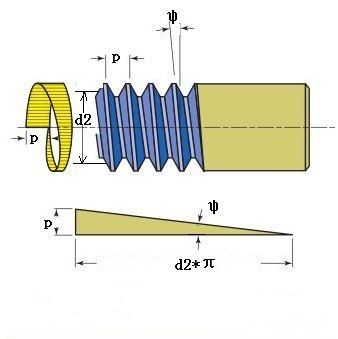

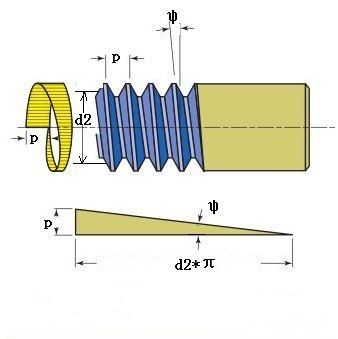

P=Pitch

d2=Basic pitch diameter of external thread

M=Tighten the bolt torque

μk=The friction coefficient between the nut and the connected part

μg=Coefficient of friction between nut and bolt thread

DKm=The center diameter of the contact ring between the nut and the connected part

Mg = friction torque between the nut and the connected part

Mk= Torque between nut and bolt thread pair (including friction torque and torque converted into clamping force)

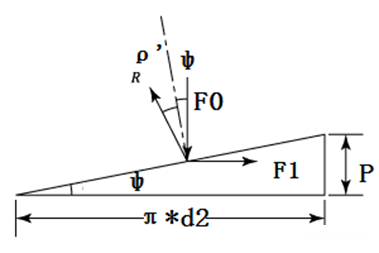

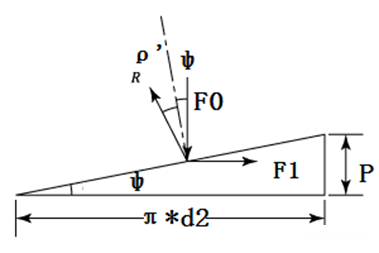

ψ=thread helix angle

2α is the thread profile angle

First look at the friction torque Mg between the nut and the connected part

Mg = F0 * ψK * Dkm/2 (Formula 1)

Expand the thread along the diameter, as shown in Figure 2, the thread helix angle

Tanψ = p/Π*d2 (Formula 2)

The analysis acting on the thread is shown in Figure 3, where the forces are balanced.

Then the component force F1 in the horizontal direction is:

F1=F0*tan(ρ’+ψ) (Formula 3)

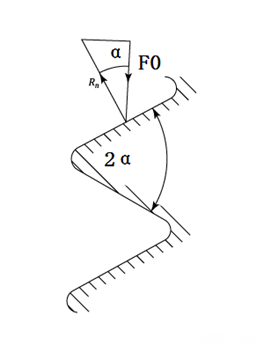

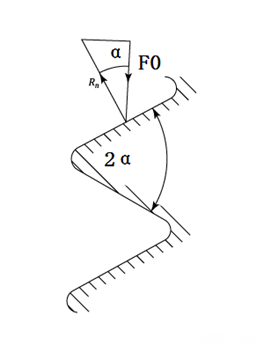

Because ordinary metric threads are triangular teeth.

Rn=The positive pressure between the nut and bolt thread contact surface

therefore:

Rn=F0/cos(ɑ) (Formula 4)

The friction force between the contact surfaces of the thread profile is

Rn*μg=F0/cos(ɑ)*μg (Formula 5)

ρ’is the friction angle

therefore:

Tanρ’ = μg/cos(ɑ) (Formula 6)

Since the thread helix angle is generally very small,

F1=F0*tan(ρ’+ψ) can be simplified to:

F1=F0*tan(ρ’)+F0* tan(ψ) (Formula 7)

Substituting formula 2 and formula 6, formula 4 can be expressed as

F1=F0*μg/cos(ɑ)+F0*P/Π*d2

Therefore: Mk= F1*d2/2=d2/2*F0(μg/cos(ɑ)+P/Π*d2)

For standard common metric threads, the profile angle 2α is 60°

Therefore: Mk=F0*(P/2*Π+d2*μg/cos30°)=F0*(0.16P+0.58*d2*μg)

Therefore, the tightening torque M can be expressed as:

M=Mk+Mg=F0*(0.16P+0.58*d2*μg)+F0*μk*Dkm/2

in:

The item containing μg is the torque to overcome the friction at the thread

The term containing μk is the torque to overcome the friction at the bearing surface of the nut

The rest is the torque converted into bolt pre-tightening force

therefore:

The torque to overcome the friction at the thread is F0*0.58*d2*μg

The torque to overcome the friction at the bearing surface of the nut is F0*μk*Dkm/2

The torque converted into bolt pre-tightening force is F0*0.16*P

Take the M30 10.9 bolt connection combination as an example to see how the bolt tightening torque is distributed under different friction coefficients.

When the friction coefficient is 0.1

Parameters of bolt nut washer

| Nominal bolt size | M30 | ISO4014 | 10.9 | |

| Pitch | 3.5 | mm | ||

| The resulting bolt pre-tightening force | 440 | KN | ||

| Bolt surface treatment | DAC500a | |||

| Friction coefficient at thread μG | 0.1 | |||

| Friction coefficient of nut bearing surface μK | 0.1 | ISO4032 | ||

| Nut bearing surface diameter dw | 42.75 | mm | ||

| Thread pitch d2 | 27.727 | mm | ||

| Inner diameter of contact surface between washer and thread dh | 35 | mm | ISO7416 | |

| 38.875 |

MA = FM(0.16*P+0.58*d2*μG+DKm/2*μK)(5.4/20)

| Tightening torque distribution | Percentage(%) | ||

| The torque to overcome the friction at the thread | 707.59 | Nm | 39.1% |

| The torque to overcome the friction of the nut bearing surface | 855.25 | Nm | 47.3% |

| The torque converted into bolt clamping force | 246.4 | Nm | 13.6% |

| Total torque | 1809.24 | Nm |

When the friction coefficient is 0.15

| Nominal bolt size | M30 | ISO4014 | 10.9 | |

| Pitch | 3.5 | mm | ||

| The resulting bolt pre-tightening force | 410 | KN | ||

| Bolt surface treatment | DAC500a | |||

| Friction coefficient at thread μG | 0.15 | |||

| Friction coefficient of nut bearing surface μK | 0.15 | ISO4032 | ||

| Nut bearing surface diameter dw | 42.75 | mm | ||

| Thread pitch d2 | 27.727 | mm | ||

| Inner diameter of contact surface between washer and thread dh | 35 | mm | ISO7416 | |

| 38.875 |

MA = FM(0.16*P+0.58*d2*μG+DKm/2*μK)(5.4/20)

| Tightening torque distribution | Percentage (%) | ||

| The torque to overcome the friction at the thread | 989.02 | Nm | 41.0% |

| The torque to overcome the friction of the nut bearing surface | 1195.40625 | Nm | 49.5% |

| The torque converted into bolt clamping force | 229.6 | Nm | 9.5% |

| Total torque | 2414.03 | Nm |

Through the above calculations, I think you have a clear answer. The coefficient of friction has a great influence on the tightening torque of bolts. When the coefficient of friction reaches 0.15, less than 10% of the torque can be converted into bolt pre-tightening force.

So is there any difference in the distribution of torque for bolts of different specifications? Welcome to leave a message to discuss!