Many bikes that have been ridden for long periods of time with no maintenance often run out of grease to lubricate the drive chain, causing the chain to stretch even more and emit a rattling or crackling noise even when just pushed along. Greasing and tensioning the drive chain is essential, but there is a trick to tensioning the chain as well, so don’t forget it.

- The first is to check the current condition of the chain.

- Surprising rider bite

- Grease up the chain after adjustment without fail.

The first is to check the current condition of the chain.

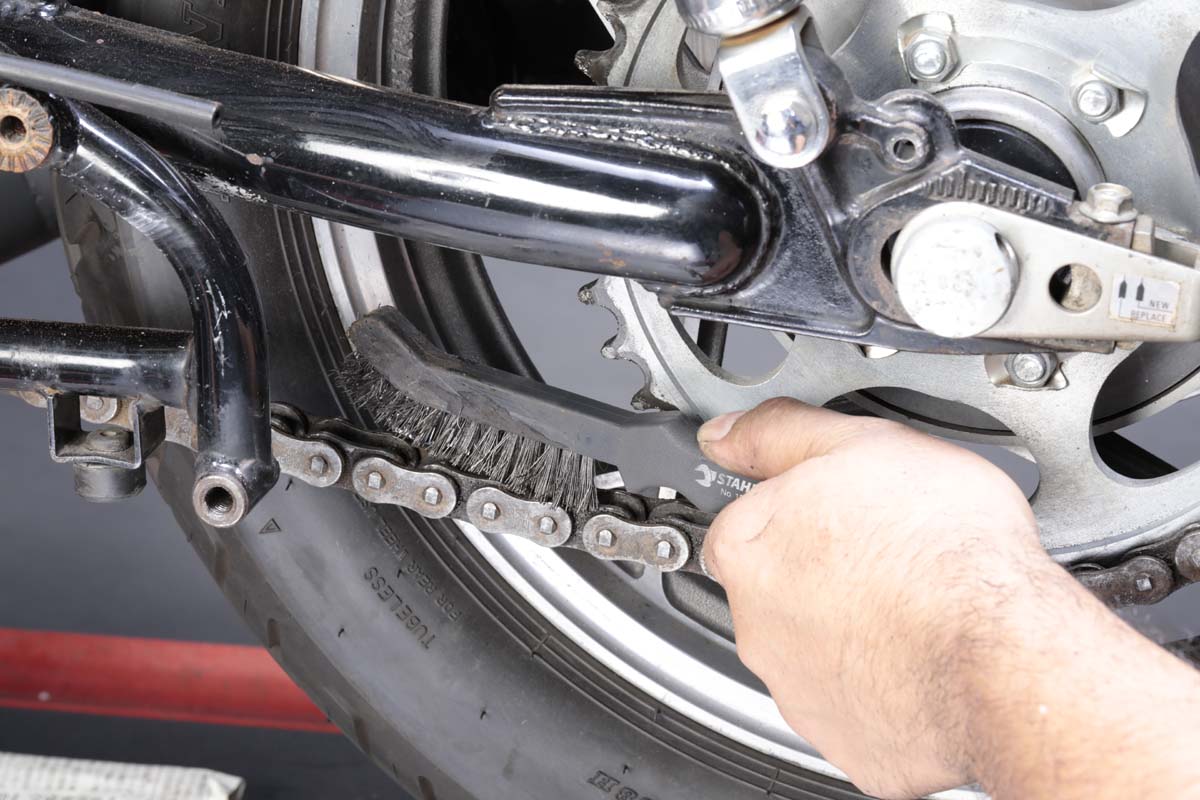

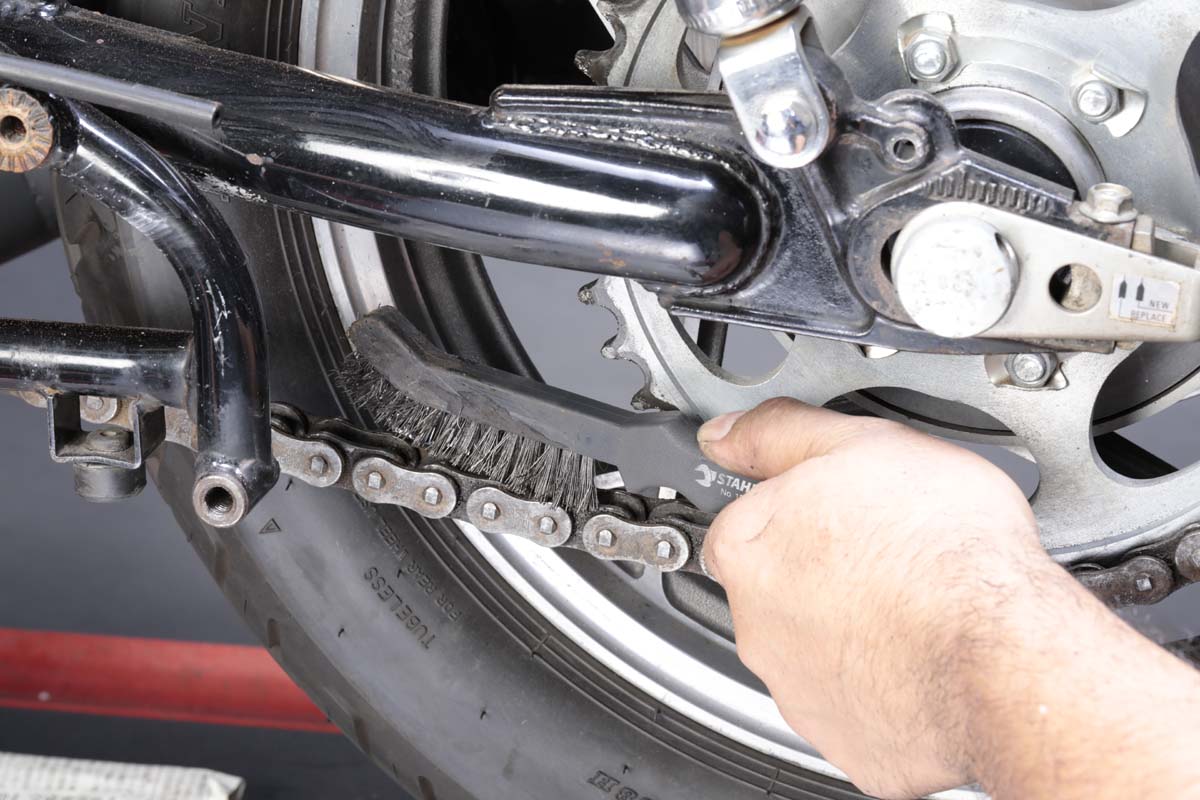

If the drive chain is not well cleaned Before starting the adjustment work, take a clean rag and lightly rub the outer side of the drive chain. If there is dirty grease on the rag, it is still good (a little lubricated!?), but if there is no dirt at all, the chain will not operate smoothly, it is possible that there is no grease at all and the chain is completely dry. If that happens, you can definitely say that there is a lack of lubrication. In such a case, you should grease up the chain with a special chemical spray, but before that, you should clean the drive chain. Spray the chain with a cleaning chemical (chain cleaner) and scrub the chain with a brush to wash off the dirt before starting the real work. Such work practices will improve the lubrication situation even more later on.

Also, there are times when you try to move the adjuster to adjust the chain, but the adjuster is reluctant to move as you wish. In such cases, the parts around the adjuster may not be sufficiently greased, so pull out the axle shaft and grease the sliding parts and shaft of the peripheral parts. This will make it easier to adjust the chain.

Surprising rider bite

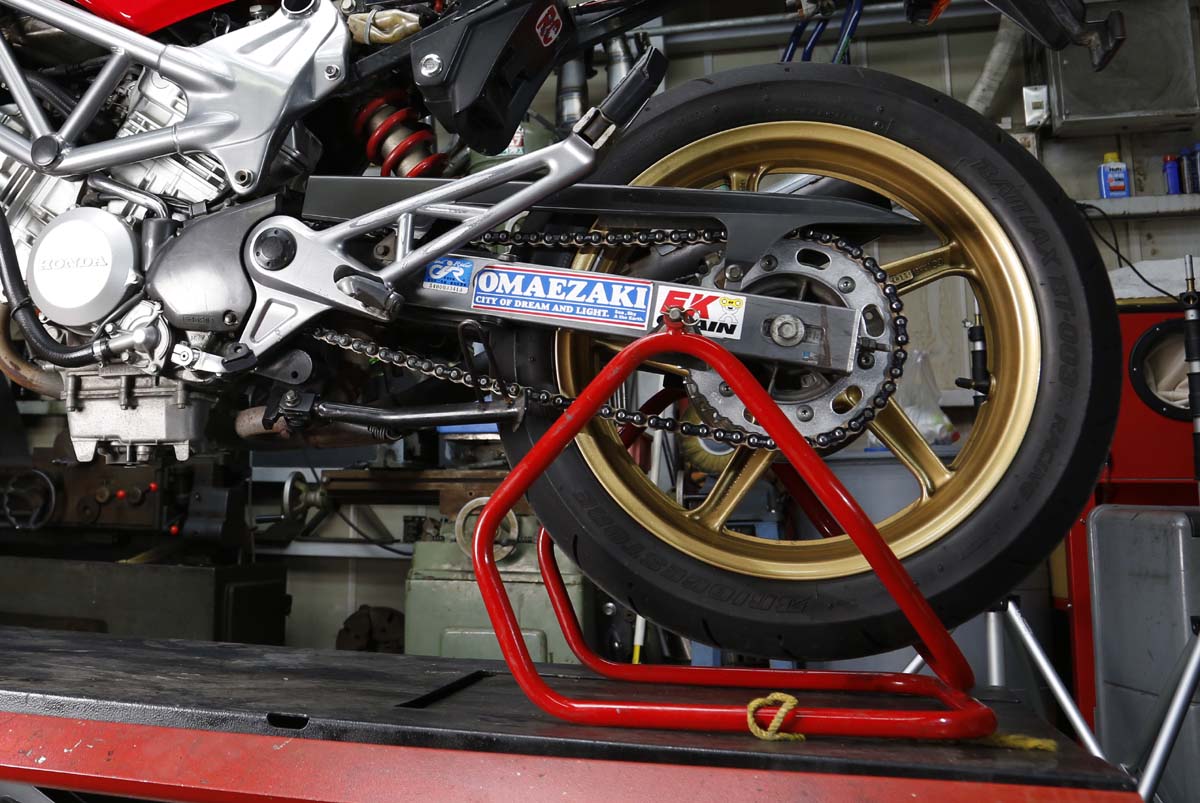

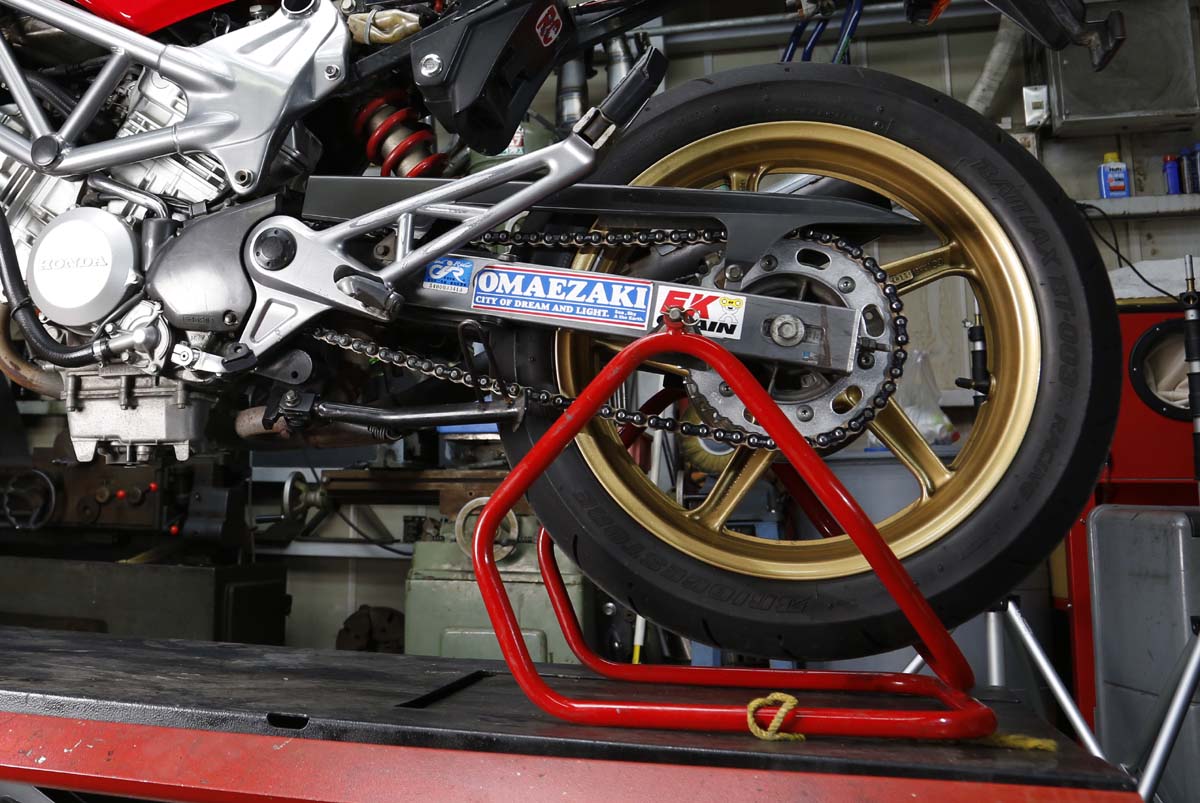

When adjusting the drive chain, the theory is that the knurled line on the swingarm’s axle shaft left/right adjusting section and the knurled line on the adjuster side should be aligned on both the left and right sides. However, when the axle shaft nuts are tightened after the adjustment, the knurled lines that should be aligned often become misaligned! This is a common occurrence. Why does this misalignment occur? To prevent such misalignment and to ensure that the adjustment work is done properly, it is advisable to engage a screwdriver or T-wrench handle in the engagement area between the driven sprocket gear and the chain, and then tighten the axle shaft nut while maintaining the chain tension.

In short, by keeping the drive chain tight, the chain adjuster is pressed against the axle shaft, and the axle shaft is held in place while keeping the chain in place. This process is extremely important. The same is true for the eccentric plate adjuster. If there are no left and right stamping lines on the swing arm, or if the stampings are too thin to see, use a tape measure (convex) to match the dimension from the center of the swing arm pivot shaft to the center of the rear axle. It can be said that confirming the dimension with a convex is a more reliable method of adjustment than matching the imprint.

Grease up the chain after adjustment without fail.

After adjusting the drive chain free play, be sure to check each tightening part to make sure that you have not forgotten to tighten it. Then, grease up the chain with a special chemical. Some riders say that they do not want to spray too much grease on the wheel because it will scatter while riding and make the wheel and rear area dirty, but this is a big mistake. After spraying the grease firmly, turn the rear wheel by hand to blend it in. Excess grease can be removed by placing a folded newspaper around the chain and rotating the rear wheel to remove the excess grease. The centrifugal force from the rotating wheel causes grease to scatter from the outer circumference, so when wiping off the grease, be sure to do it from the outside of the chain and not from the inside of the chain.