Price differences: Why do thread cutting assortments cost so much or so little?

Have you also noticed the price differences when researching for a good thread cutting assortment? What is the reason that the thread cutting sets are either very cheap or perceived to be very expensive? Does a red metal cassette cost less than a blue or green one? Are the tools in the cassettes really all the same in terms of quality? What is the difference between WS and HSS tools?

In this article, we want to get to the bottom of these questions and help you find the right threading assortment for you. Have fun reading!

Especially on the marketplaces like Amazon and Ebay, you can always find very cheap taps, dies or complete thread-stenoid assortments as well as sets. In the research, the pictures of the tools also all look the same or undercut only in the color of the cassettes. But the color of the cassettes can not explain the sometimes very high or low prices. Is it then due to the brand product? What is happening here?

Why do thread cutting sets differ so much in price?

You already guessed it, the price differences are due to the quality, among other things. Here it is important to draw attention to some features of the sets. Among them: Equipment and extent of the cassettes, processing and quality claim, processed raw materials, seller or dealer and manufacturer, etc.

- Cassette assembly and volume

- Processing and quality standards

- Processed raw materials

- Manufacturers and dealers, etc.

Equipment and scope of threading assortments

The price differences may depend on the size of the set in the first step. Is it a 32-piece set or a 48-piece set? What thread diameters are covered in the assortment? What tools are all included in the set?

Most assortments cover the sizes M3 – M12. But there are also assortments up to M20 or also M24 or also inch thread types. Another difference is made by the holding tools, HSS twist drills, hand tap guides, die guides, etc.

How can you tell what you’re buying by looking at the description?

It is important that you take a close look at the item description of manufacturers and dealers. This is because some dealers obscure the description so that you can’t necessarily tell at first glance what the tools are made of. Others use click-worthy keywords such as HSS drill bits in the article title. This is common practice on the relevant online marketplaces to list drilling as well as threading tools. In addition, it is very popular to write about HSS drills in the article description, which are not even included in the scope of delivery.

But what if the retailer or manufacturer does not even provide any information about this in the item description? If you want to be on the safe side, you should write directly to the manufacturer or dealer.

Tool steel and high-speed steel for thread cutters

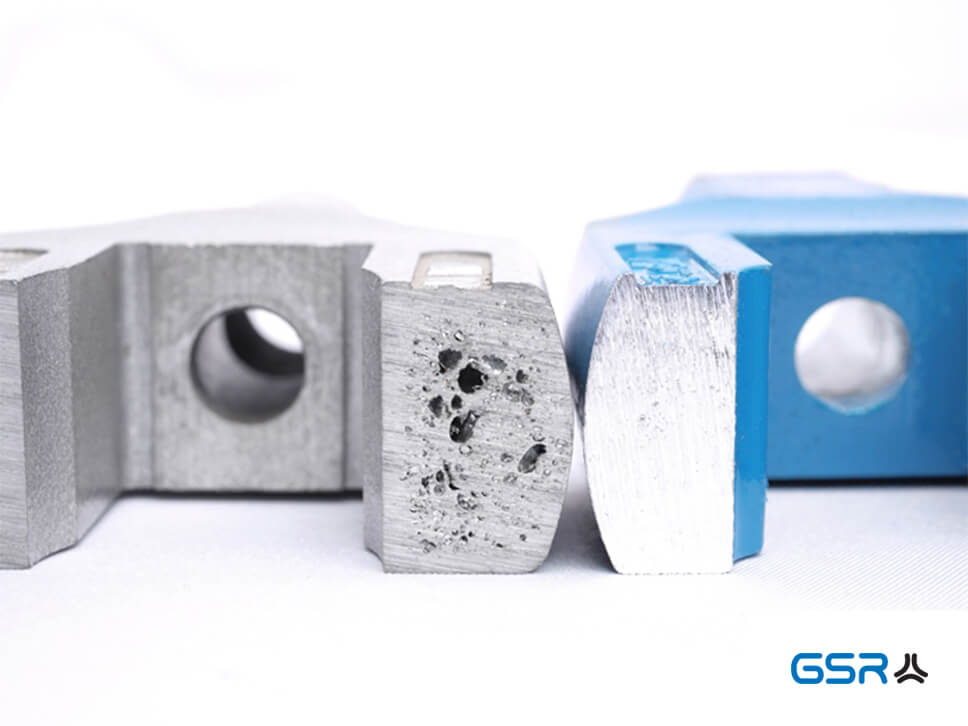

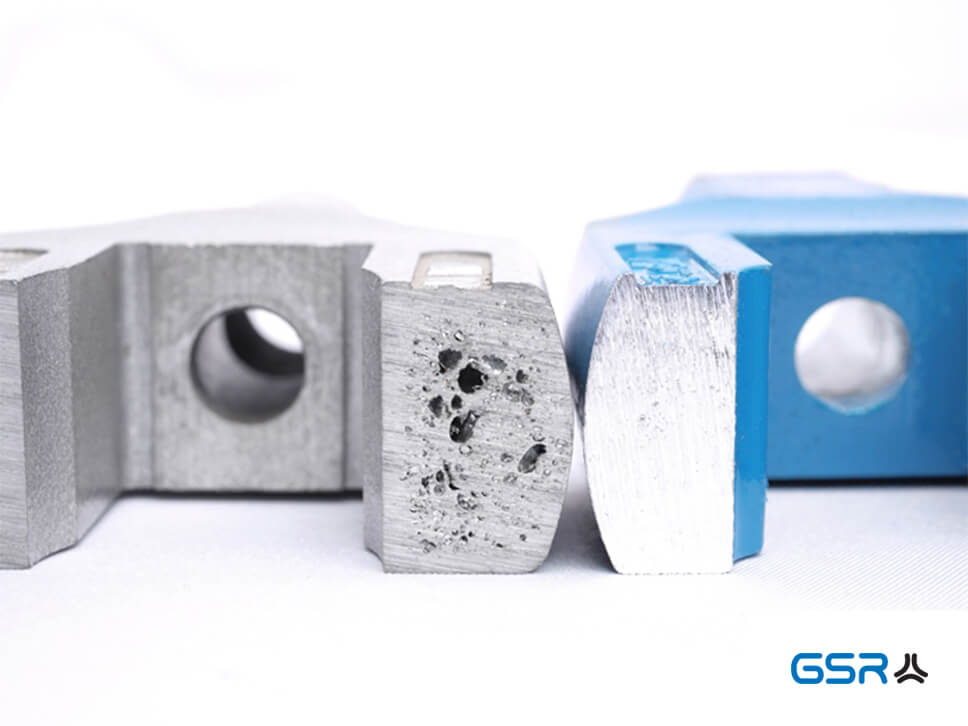

In the description of threading assortments, a closer look reveals the designation tool steel (WS) and high-speed steel (HSS). This is one of the main differences why prices vary so much.

Incidentally, this applies not only to the ranges but to all cutting tools, such as hand taps, machine taps, dies, drill bits, etc.

This is because taps made of tool steel are more suitable for re-tapping threads. Tapping of soft materials and low alloy structural steels is also well feasible with WS tools. However, you have to make concessions here in terms of thread tolerance.

With HSS tools, on the other hand, you can also cut threads in alloyed belly steels, free-cutting steels or even stainless steels.

Which set is better for you depends on the application. Do you cut rather infrequently and have to recut a thread in soft materials (plastic, aluminum, etc.)? Then you should take a look at the WS sets. Please note that the tolerance can be inaccurate here.

Do you frequently recut threads? Do you need an exact thread tolerance? Do you also want to cut threads in harder materials such as alloyed structural steels?

Then you should rather invest in a HSS thread cutting assortment. HSS threading tools are always more expensive and of higher value than WS tools.

How can you tell what you’re buying by looking at the description?

It is important that you take a close look at the item description of manufacturers and dealers. This is because some dealers obscure the description so that you can’t necessarily tell at first glance what the tools are made of. Others use click-worthy keywords such as HSS drill bits in the article title. This is common practice on the relevant online marketplaces to list drilling as well as threading tools. In addition, it is very popular to write about HSS drills in the article description, which are not even included in the scope of delivery.

But what if the retailer or manufacturer does not even provide any information about this in the item description? If you want to be on the safe side, you should write directly to the manufacturer or dealer.

DIN and factory standard for threading tools

Another price distinction arises when a threading tool is manufactured according to DIN standards. In this case, the tolerance is adhered to more precisely than in the case of tools manufactured to factory standards. Accordingly, DIN tools are somewhat more expensive, since higher quality is already assumed during production. Many manufacturers mark their tools with the DIN identification. If there is no marking, it is still very easy to recognize a tap or a die according to DIN by its workmanship. Pay attention to the shaping of the tip, the flutes, the profile and the run-out.

Packaging Metal cassette, wooden cassette and plastic cassette.

There are also significant differences in the outer packaging that influence the price. The wooden cassette is the most expensive variant here. Although these are very sustainable as well as optically very valuable, they are hardly offered, because a customer is not willing to pay the money compared to the cheaper metal and plastic boxes. On the various marketplaces you can find more and more assortments packed in plastic boxes and assortments in metal cassettes. The metal cassettes also differ in the material used and the sheet thickness. If the cassettes are manufactured and coated in Europe, they are correspondingly more expensive than if they come from other Asian countries.

Tools holders with low alloy zinc casting or highperformance Zamak-5 zinc casting

The adjustable tap wrenches and die holders can also be manufactured according to factory standard or DIN. In addition, the manufacturing process plays a major role in the body as well as the toggles of the holding tools.

Comparison article: How can you recognise a good adjustable tap wrench?

How can you recognise a good adjustable tap wrench?

Essentially, the new tools holders have a different body geometry that results in higher torque. If you take a closer look at the adjustable winch, for example, you will immediately notice the honeycomb shape on the handle holder. Another important point is the material used in the base body. Because not all zinc die casting is the same. The holding tools with honeycomb shape geometry always have the zinc die casting alloy Zamak-5 (EN 1774).

GSR Gustav Stursberg is the only manufacturer and supplier of these unique tool holders.

Conclusion thread cutting assortments in comparison

The price differences have primarily to do with the quality of the tools. When deciding on a purchase, you should therefore know beforehand for what purpose you need the tools. Is a thread only to be recut? Then the purchase of a WS thread cutting assortment in red or green cassette is sufficient. Do you only cut two threads in aluminum or zinc once a year? Then a WS set is also sufficient. But still pay attention to the quality of the tool! There are very many WS quality levels.

Are you an ambitious professional craftsman or metalworker? Do you cut threads often? Do you machine all kinds of materials from aluminum to quality structural steels, such as ST52, to stainless steels like 4571? Do you want to have fun with thread cutting?

Then we definitely recommend you to buy an HSS thread cutting assortment in a gray industrial cassette according to DIN.

The same is true for the individual threading tools. The more demanding and precise the project, the more you should rely on HSS manufactured tools.

Our HSS Threading Assortments

- 32 piece threading cassette M3-M12 HSS – Product number: 00708070 (Go to Shop)

- 45 piece threading cassette M3-M12 HSS – Product number: 00708080 (Go to Shop)

- 48 piece threading cassette M3-M12 HSS with guides – Product number: 08333800 (Go to Shop)

- 56 piece threading cassette M3-M20 HSS – Product number: 08331040 (Go to Shop)

- 64 piece threading cassette M3-M24 HSS – Product number: 08331050 (Go to Shop)

- 33-Piece Beginner Metalworking Assortment – Product number: Quote-11 (Go to Shop)

Other helpful sources:

- No.1 Thread determination with inch thread

- No.2 Determination of metric threads

- No.3 Thread determination for UN vintage thread

- No.4 Thread determination: UNF engine block of a Land Rover

- No.5 Thread determonation for objective lens treads

- How to use a thread template correctly: go to the tutorial on Youtube!

Did you like this article? Do you have any questions or feedback? Write to us.

Do you also need to determine a thread? Do you need help? Feel free to contact us!