Hydraulic clutches are mainly used in high-end and expensive vehicles.

The clutch does not need to be maintained by lubricating the wires (although it is necessary to lubricate the lever pivots, etc., so it is not completely maintenance-free), and there is no need to worry about it suddenly disengaging while touring, as is the case with a wire type clutch. This is the reason why a large percentage of large motorcycles use this type of clutch.

Some of you may have admired this hydraulic clutch because it is used in your coveted luxury notorcycles. There are even kits available to convert a wire-type clutch to hydraulic.

Example of hydraulic clutch conversion of a grom

Example of using a general-purpose clutch master cylinder made by Magura

In such a situation, many people seem to set the hydraulic clutch reservoir tank to the MAX level, just as they keep the reservoir tank fluid level of hydraulic brakes to the maximum level.

If the MAX level is exactly right, there is no problem because it is within the specified range, but in fact, it is the theme of this issue.

- Why is the hydraulic system used?

- Advantages and disadvantages of hydraulic clutches

- Hydraulic system, so there is a reservoir tank on the handle side.

- It’s a reservoir tank, so the liquid level is specified.

- Clutch reservoir tank fluid level should not be maxed out

- So wouldn’t it be best to keep the liquid level further below the lower limit?

- Summary

- Personally, I prefer the wire type.

Why is the hydraulic system used?

The reason why hydraulic clutches are used in many heavy-duty vehicles is that, in addition to the above maintenance-free features, the wire-type clutch does not allow the clutch to change its connection position while the vehicle is in motion.

A large-capacity clutch designed to handle high power inevitably has a large number of clutch plates, so it is a fate that the clutch connection position tends to change when the half-clutch is used frequently.

In a wire type clutch, the clutch connection position (=meet point) changes with slight changes in the clutch plates (thinning due to wear of the friction plates or thickening due to expansion from the heat of the half-clutch), but in a hydraulic type clutch, the meet point does not change due to its structure. However, hydraulic clutches do not change the meet point due to their structure.

The hydraulic type, on the other hand, does not change the clutch meet point due to its structure.

So the emphasis is on ease of operation that allows clutch meat to always be in the same position.

Why does the hydraulic system not change the meet point? The reason is easy to understand if we imagine it in terms of brakes. Imagine the lever position of a wire-operated brake and a hydraulically operated brake when the pads and shoes wear down.

With wire-operated brakes, the lever position moves further and further forward as the brake shoes wear down, but with hydraulic brakes, the lever position does not change even if the brake pads wear down, right? It is the same.

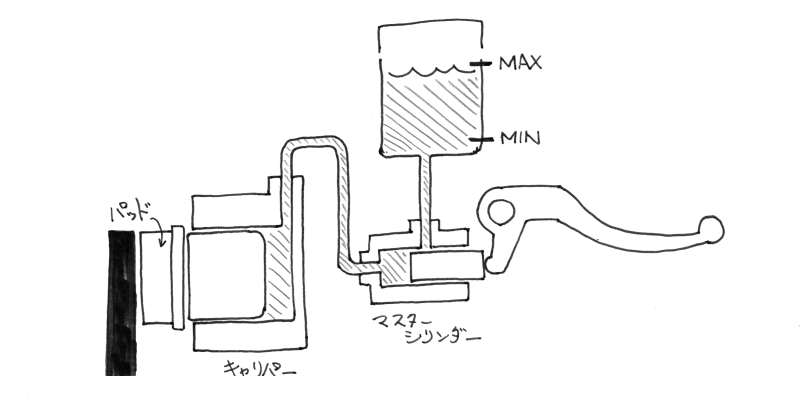

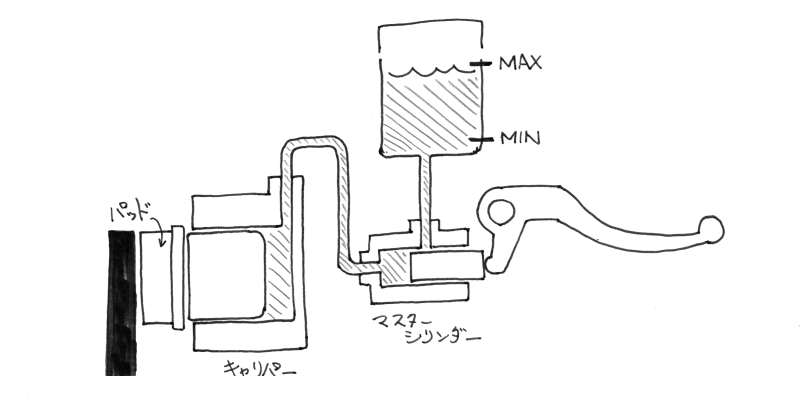

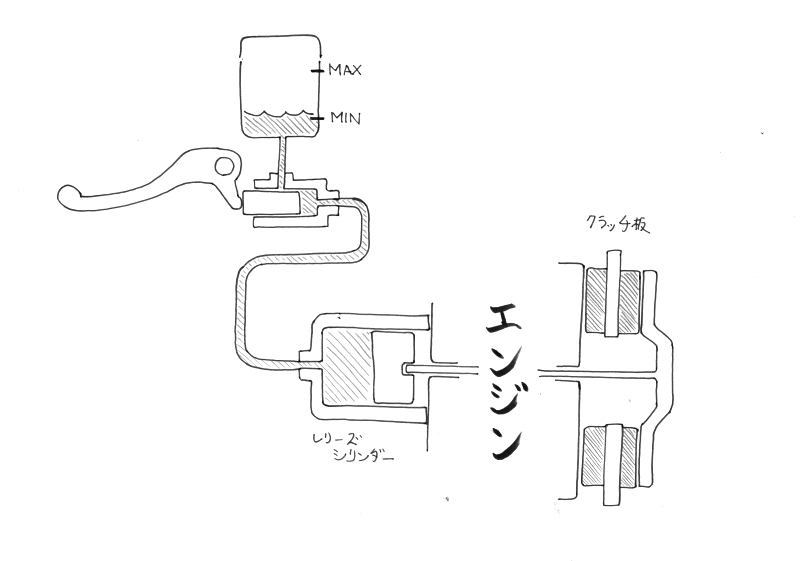

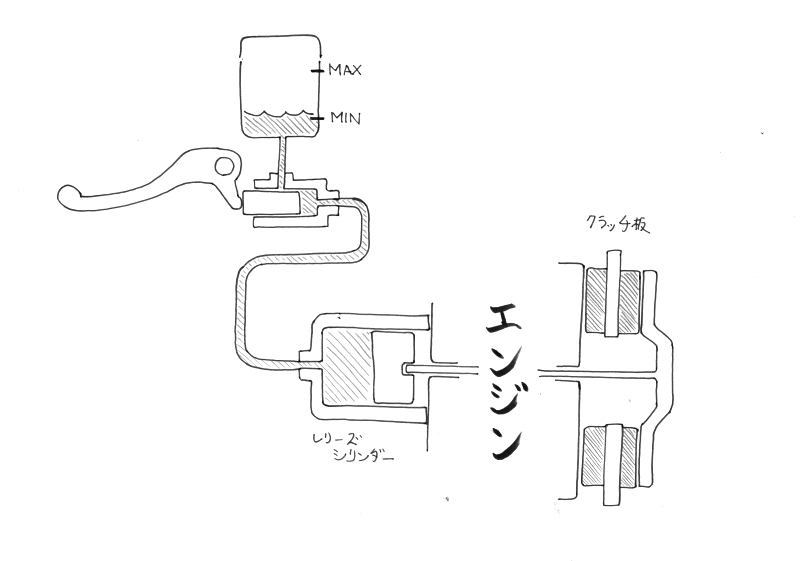

I tried to make an easy-to-understand diagram, but I didn’t have time, so I decided to go out on a limb and draw it freehand.

I simplified it so much that it is a little different from the actual cross section, but it looks roughly like this.

▲▲▲ Figure when pads are new on brakes ▲▲▲▲

▲▲▲ Figure when pads are reduced by brakes ▲▲▲▲

The lever position hasn’t changed, has it?

Advantages and disadvantages of hydraulic clutches

This is why hydraulic clutches are often used in large and high-end vehicles, but unfortunately, they are not a panacea and have some disadvantages.

A brief summary is as follows

- No sudden wire breakage when you are out and about.

- No need to lubricate wires

- Clutch meat position is always constant and unchanging

- Light lever operating force (in many cases)

- Luxury.

- Looks cool.

- Complex structure

- High price due to many parts

- Component weight is heavier than wire type

- The lever is heavy when held in the grip.

- Clutch meat does not feel good.

The hydraulic system has the tremendous advantage that there is no resistance associated with its operation like the wire system, and since it uses Pascal’s principle, the lever operation force is light. However, in fact, there are situations where this is a disadvantage.

That is, if the clutch is held in the clutch while waiting at a traffic light, etc., it is constantly subjected to the reaction force of the clutch spring.

In the wire type clutch, the inner and outer parts of the wire rub against each other, creating contact resistance, so once the clutch is gripped, the operating force is lost due to the contact resistance.

However, it is not good for the clutch release bearing (the bearing that takes the entire force of the clutch spring when the clutch is disengaged) to keep the clutch depressed at a stoplight in the first place, so it is a good idea to put the clutch in neutral when stopped.

In addition, some supersport models of large motorcycles also dare to use a wire type clutch, in order to save weight and to give a better feeling of operation when the clutch is engaged.

So not everything is the best and strongest hydraulic type.

For example, the Yamaha YZF-R1 has always used a wire clutch!

Hydraulic system, so there is a reservoir tank on the handle side.

Hydraulic clutches, like hydraulic brakes, require a reservoir tank on the handle side to hold hydraulic oil.

There are two types: a “square tank type” integrated with the master cylinder and a “separate type” with an independent tank, both of which function in the same way to store hydraulic oil.

The function of both types of brake reservoirs is identical to that of hydraulic brakes.

As a side note, hydraulic fluid for hydraulic clutches is exactly the same as brake fluid. There is no such thing as “fluid for hydraulic clutches,” so feel free to use brake fluid even for clutches!

Example of clutch master cylinder with separate reservoir tank

Cool!

Example of a stock clutch master cylinder called a “square tank” or “integral type

Generally, this is the mainstream

It’s a reservoir tank, so the liquid level is specified.

Just as hydraulic brake reservoir tanks have upper and lower fluid level designation lines, clutch reservoir tanks also have upper and lower fluid level designation lines.

Some car models even use the exact same reservoir tank as the brakes.

As is well known, in the case of hydraulic brakes, the fluid level should be set to the “MAX (UPPER)” position, which is the upper limit.

This is because when brake pads are reduced, brake fluid is automatically replenished from the reservoir tank to absorb the volume of the caliper piston that has been contained within the caliper, which pops out as the pads are reduced.

It is safe as long as it is between the upper limit (MAX) and the lower limit (MIN, LOWER), but it is safer to set it to MAX.

If the fluid level was at the lower limit from the beginning, the reservoir tank would be empty because the brake pads would not be able to replenish the amount of fluid that has been reduced.

If the reservoir tank is empty, the caliper piston cannot pop out, and at worst, the brakes will not work even if the lever is squeezed, which is very dangerous.

Since there is no fluid, air can get into the master cylinder, which is the same thing as the vapor lock phenomenon (where the brake boils and air gets into the hydraulic path), which again is dangerous because the brake will not work even if the lever is squeezed.

As an aside, if brake fluid is replenished to the max level when the brake pads are depleted, brake fluid will overflow from the reservoir tank by the pistons pushed back into the calipers when the pads are replaced with new ones.

If the fluid was replenished during the process before pad replacement, the brake fluid in the reservoir tank should be sucked out and reduced before replacing with new pads.

Now, just like brake pads, clutches wear out and decrease with use, and they consist of a master cylinder and release piston (equivalent to a caliper), and I’m sure there are a lot of people who set their clutch reservoir tank fluid level to “max”, the upper limit.

However, this is not the case on the clutch side.

Example of “MAX” and “MIN” display

Example of “UPPER” and “LOWER” display

Clutch reservoir tank fluid level should not be maxed out

Actually, the clutch side should be set near the lower limit of the allowable fluid level line, “LOWER” or “MIN”.

But why should the clutch side not be set to MAX fluid level when it uses almost the same system as the brake and the clutch plate (friction plate) is also something that decreases?

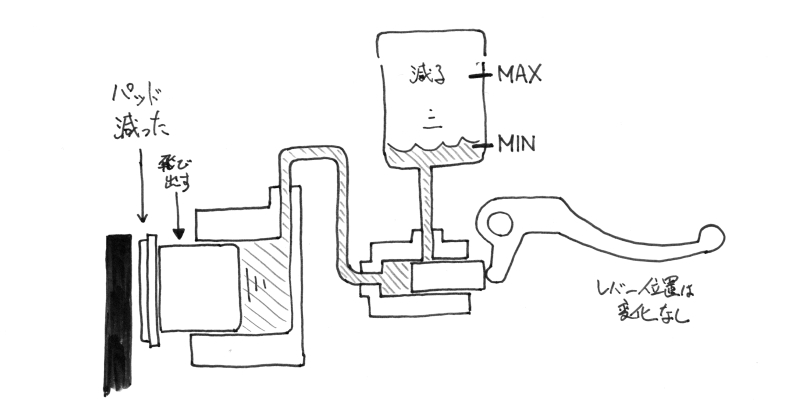

This is because, contrary to the brakes, the more the clutch plate (friction plate) is used and reduced, the more the piston on the release side is pushed back.

When the piston is pushed back, the level of fluid in the reservoir tank rises by the volume of the fluid that is pushed back into the reservoir tank, but the position of the clutch lever does not change.

If the fluid is filled to the max position when the clutch is new, there is no escape for the fluid that comes back when the clutch is depleted, and the clutch will slip easily.

The release piston cannot return to the clutch, so the clutch pressure drops and the clutch slips.

When the clutch started slipping even though there was still plenty of thickness left, I changed the clutch fluid just to be safe and that fixed it! Has anyone had this experience?

This may be due to the fact that the reservoir tank had risen to its maximum level, but by replacing the fluid, the fluid level was lowered to the maximum level and the clutch was able to connect properly.

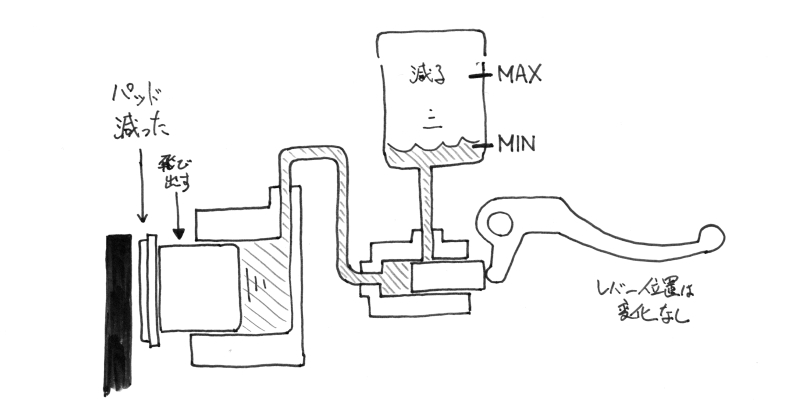

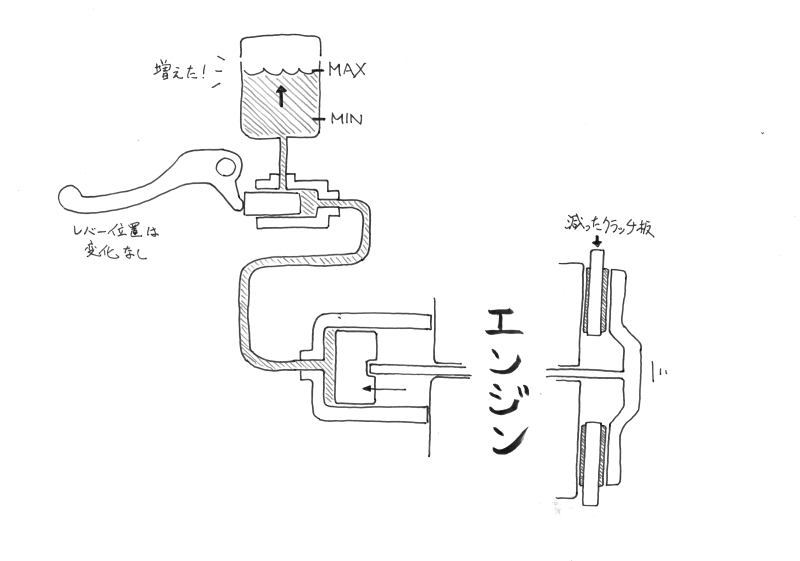

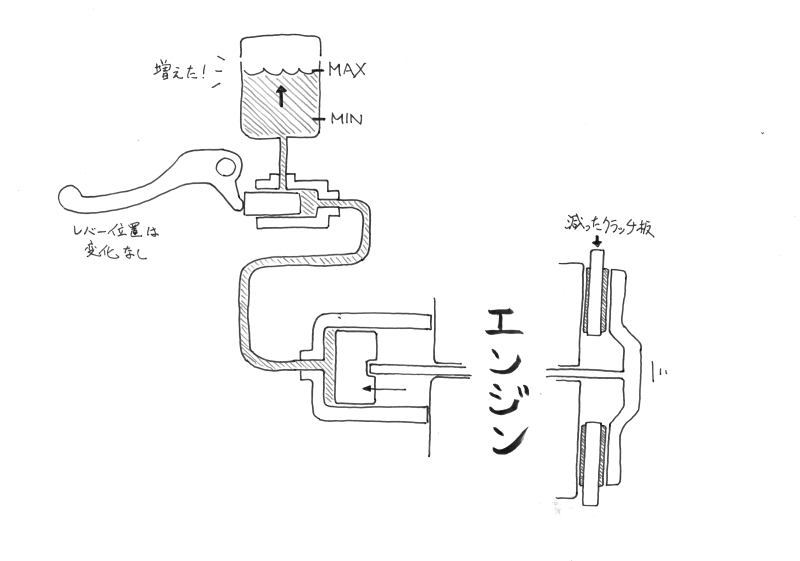

This is also difficult to understand in words, so I have made a diagram of it.

As usual, it’s “freehand handwriting,” but it’s obvious at a glance! (Hazmat)

▲▲▲ Figure when clutch friction plate is new ▲▲▲

▲▲▲ Figure when the friction plate of the clutch is reduced ▲▲▲▲

The lever position does not change as the fluid level in the reservoir tank rises

Also, if the fluid level was maxed out from the beginning, there would be no place for the fluid to escape, so the piston would not be able to return, and you can see that the clutch plate would not have enough crimping force, right?

So wouldn’t it be best to keep the liquid level further below the lower limit?

Some may think so. But you can’t make it lower than the lower limit level.

The fluid level rises as the clutch plate decreases, but the hydraulic clutch is characterized by the fact that during normal use, a considerable amount of fluid moves back and forth between the master cylinder side and release piston side each time the clutch lever is depressed.

This is a major difference from the brake side, where the fluid hardly moves and only pressure is transmitted. (There is some fluid movement on the brake side as well.)

Because it is such a hydraulic clutch, it can chew air quite easily if the fluid level is low.

If the tank is a separate reservoir tank type that can be oriented upright, but if the fluid level is too low in a tank-integrated master cylinder, it will chew air more easily than you can imagine.

I have had the experience of doing this myself, but when air gets trapped in a hydraulic clutch, the clutch becomes harder and harder to disengage while driving, and eventually the clutch will not disengage at all even when the lever is depressed.

The reason why it won’t disengage is that it only compresses the air that is mixed in, but it gets worse and worse while driving, so it’s quite frustrating.

Liquid level must not fall below the lower limit

Summary

A genuine hydraulic clutch, correctly set up by the manufacturer, is designed to be light to grip despite its large capacity and strength to withstand large displacement and large power.

It is basically maintenance-free, rarely breaks down, and is not associated with mechanical problems such as sudden wire breakage.

Even if the clutch wears out, the lever position does not change, and you can always operate the clutch with the same feeling, that’s the hydraulic clutch! Fantastic!!!

Clutch fluid is OK as long as it is between the MAX and MIN lines, but it is safer to keep it near the MIN if possible.

The reason for this is that there is more room for the fluid level to rise when the clutch plates wear out.

It is OK to set it at the upper limit of the MAX line, but be careful about the fluid level rising, because the clutch may slip if the fluid level rises!

But that doesn’t mean you can’t go below MIN, because then you’ll chew air and the clutch won’t disengage!

And the reason for all of this is that, unlike the brake side, the amount of fluid in the reservoir tank increases when the clutch plate decreases.

This is the key to this story.

Personally, I prefer the wire type.

Although hydraulic systems have many advantages, they often focus on reducing lever operation force, which tends to increase the amount of lever operation.

This is unavoidable because there is a trade-off between reduced lever operation force and increased lever operation volume.

But I am the type of person who does not use the half clutch to the extreme. I do not use the half clutch to absorb the shift shock when downshifting, and I almost never use the half clutch even at the start of the shift.

Since the number of lever operations is small, it is more important to have a quick cut and a quick connection than to have a light operation!

Therefore, I prefer the wire type, which has a more direct feel, even if the lever is a little heavier.

In addition, auto shifters are becoming more popular these days, and an increasing number of vehicles do not require any clutch lever operation for shifting up or down once the vehicle is underway.

If they are not going to be operated anyway, perhaps the number of wire-type systems with simple mechanisms will increase in the future.

But if we aim for maintenance-free operation, the hydraulic type has an advantage, and I wonder what will happen to it?